Efficient Welding

Welding is a critical component of our manufacturing process. For nearly 50 years, Flextur has invested in skilled people and advanced equipment to enhance our welding capabilities. Our expertise in robotic, manual, and specialty welding processes allows us to minimize setup times and reduce variable costs while ensuring strong repeatable welds. Whether it’s a high-volume production or intricate one-off parts, we provide reliable welding solutions tailored to your needs.

Capabilities That Set Us Apart:

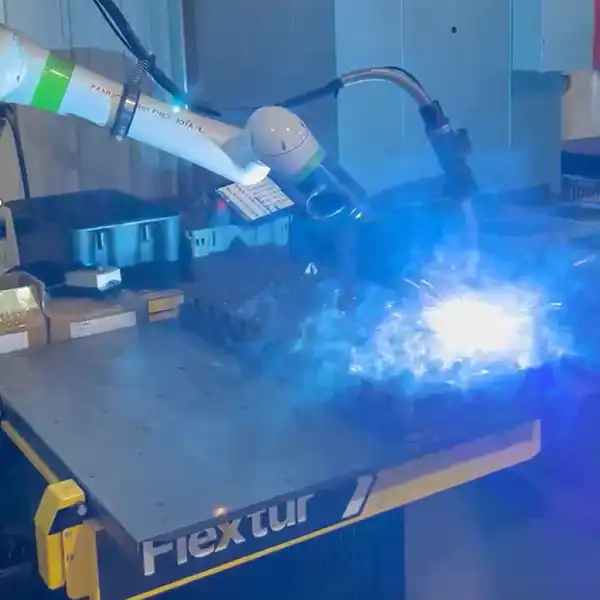

Robotic Welding

- High-Speed Precision: Our high-speed robotic welders construct reliable and repeatable welds, built on fixtures and tooling made in-house.

- Advanced Integration: Our robotic systems incorporate technologies such as robots and cobots to meet diverse production needs.

Manual Welding

- Expert Craftsmanship: Our experienced manual welders and programmers meet numerous AWS standards through continuous in-house and external training. This commitment ensures our customers receive consistent, high-quality welded products.

Benefits of Partnering with Flextur

Fixturing

Fixturing is the backbone of our welding capabilities. Our team rapidly develops simple, cost-effective fixtures to enhance repeatability and ensure seamless automation. Unlike traditional machined aluminum fixtures that become obsolete with design changes, our fixtures are designed to wrap, hold, and clamp parts strategically—essential for efficient robotic welding.

Collaborative Teamwork

Beyond automation, our skilled manual welders, fixture builders, and programmers work in sync to create an environment of efficiency and quality. “We have a team that flexes to the need, carefully inspecting each part before it moves forward,” says Welding Supervisor Rueben Bowman Jr. This collaborative approach ensures consistent, high-quality results for both internal and external customers.

Our Equipment

OTC Robotic Welding Cells

- Head & Tail Stock Positioner – Enables Full 360-degree rotation of workpieces, ensuring optimal welding access and positioning

- 6 Axis Robot

- Extended Reach - Approx. 10 ft.

- Consistent Repeatability: +/- 0.08mm

TECNA 7913 Spot Welder

- Water-Cooled

- Pneumatic Operation

- 8 lb max electrode force

Manual Welding Cells

- Powered by OTC

- Paired with Flextur Welding Tables

Fanuc Cobot Cell CRX-10iA

- 6 Axis Cobot

- Reach Approx. 4 ft.

- Consistent Repeatability: +/- 0.04mm

- 10kg Payload Capacity

- Ideal for High-Mix, Low-Volume Manufacturing

- Paired with pneumatic Quick-Change Tables

Yaskawa Cobot Cell HC10XP

- 6 Axis Cobot

- Reach Approx. 4 ft.

- Consistent Repeatability: +/- 0.1mm

- 10kg Payload Capacity

- Paired with pneumatic Quick-Change Tables

Frequently Asked Questions

Robotic welding uses MIG welding with various wire types. Robots follow programmed welding points for continuous, precise welds.

Manual welding is preferred when working on small batches or highly customized projects.

Look for comprehensive services, extensive experience, and a proven track record of quality.

Full penetration, smooth finish, minimal discoloration, and uniformity.

Increased repeatability, accuracy, and speed, leading to higher-quality welds and reduced rework.