Precision CNC Machining for High-Performance Manufacturing

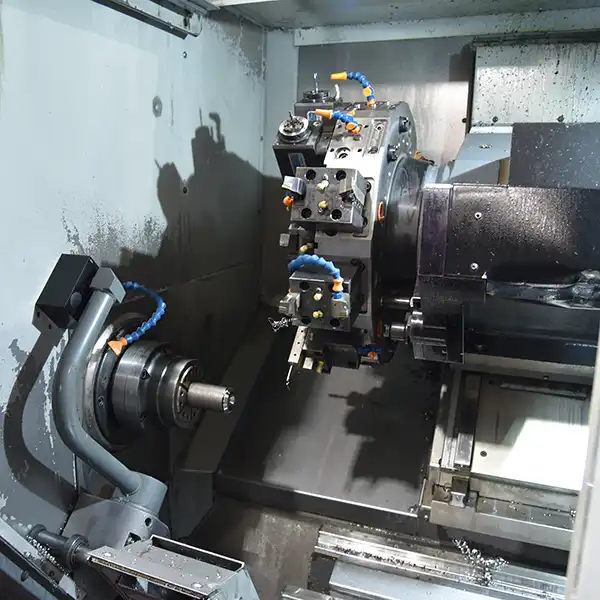

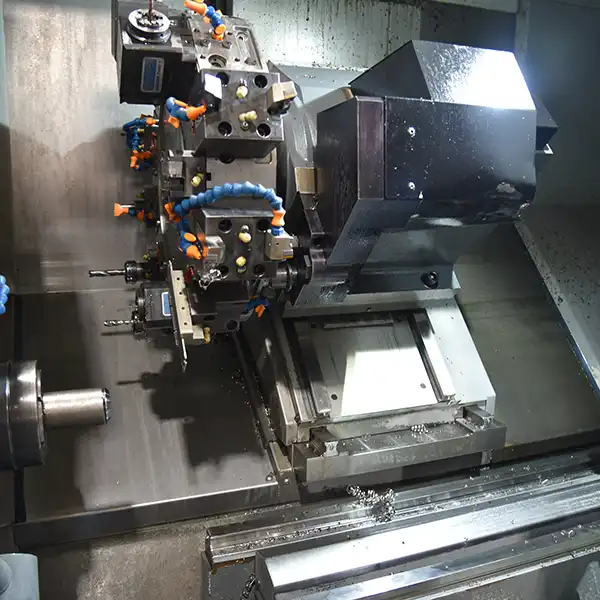

Looking for precision CNC machining services that deliver high accuracy, efficiency, and cost savings? At Flextur, we provide advanced CNC lathe machining using the Haas DS-30SSY CNC Machining Center, ensuring tight tolerances, superior surface finishes, and reduced lead times.

Our contract CNC machining services support a variety of industries, including aerospace, automotive, industrial manufacturing, and metal fabrication. Whether you need prototyping or high-volume production, our CNC turning and milling capabilities produce durable, high-quality parts to meet your exact specifications.

Capabilities That Set Us Apart:

- Dual-Spindle CNC Machining: Complete complex parts in a single setup, improving accuracy and efficiency.

- Y-Axis Machining: Enables off-center milling, drilling, and tapping for intricate features.

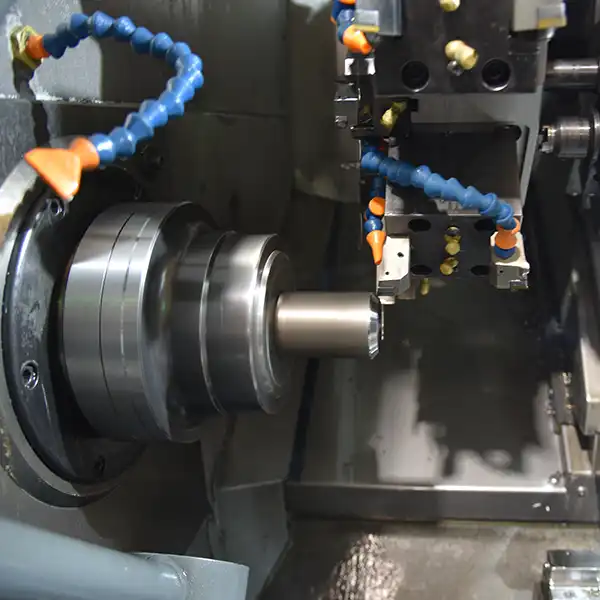

- Large Part Machining Capacity - Handles parts up to 16 inches in diameter and 23 inches in length.

- Live Tooling with C-Axis Control: Eliminates the need for secondary operations by integrating milling, threading, and drilling.

- Multi-Material Processing – Precision machining of aluminum, stainless steel, mild steel and other metals to meet the needs of diverse industries.

Benefits of Partnering with Flextur

Consistent Quality & Precision

Our precision CNC machining technology ensures parts meet exact tolerances and surface finish requirements.

Cost-Effective Manufacturing

Single-Setup machining reduces cycle times and material waste, improving cost efficiency.

Scalability & Versatility

Whether you need custom prototypes, short-run production, or large-scale manufacturing, we can accommodate your needs.

Industry Expertise

With decades of experience in precision metal fabrication, we understand the challenges of industrial manufacturing and provide solutions that improve performance and durability.

Fast Turnaround Times

With efficient programming, optimized tool paths, and multi-axis machining, we deliver shorter lead times without sacrificing quality.

Our Equipment

HAAS DS30SSY CNC Machining Center

- Dual-Spindle, Y-Axis Turning: Allows for multi-axis machining with fewer setups, increasing efficiency.

- Max Turning Diameter: 16.0” | Max Cutting Length: 23.0”

- Live Tooling & C-Axis: Enables milling, drilling, and tapping in a single setup.

- High-Speed Machining: 4,500 RPM spindle speed for rapid material removal and improved cycle times.

Frequently Asked Questions

We specialize in precision CNC turning, milling, and multi-axis machining, capable of handling complex parts and tight tolerances.

We work with aluminum, stainless steel, titanium, brass, copper, plastics, and other specialty materials.

Yes! We offer both prototype and full-scale production machining to meet your needs.

Absolutely. Our multi-axis CNC capabilities allow us to produce intricate and highly detailed parts with precision.