Sheet Metal Fabrication

Contract Metal Manufacturing

High-quality steel products that exceed your expectations and are completed on time.

Give us a call when you need more bandwidth, skills, or team members to complete your project. Flextur's sheet metal fabrication and contract metal manufacturing services will help you meet deadlines with the highest quality end product.

Our customers typically come to us for one of these six reasons:

Seeking a single source solution to cut, form, machine, weld, coat and deliver on time.

Labor shortages or workforce development challenges.

Need assistance meeting production, quality, or financial goals.

Supplier or supply chain challenges.

Value engineering services or product design.

On time delivery & superior logistics.

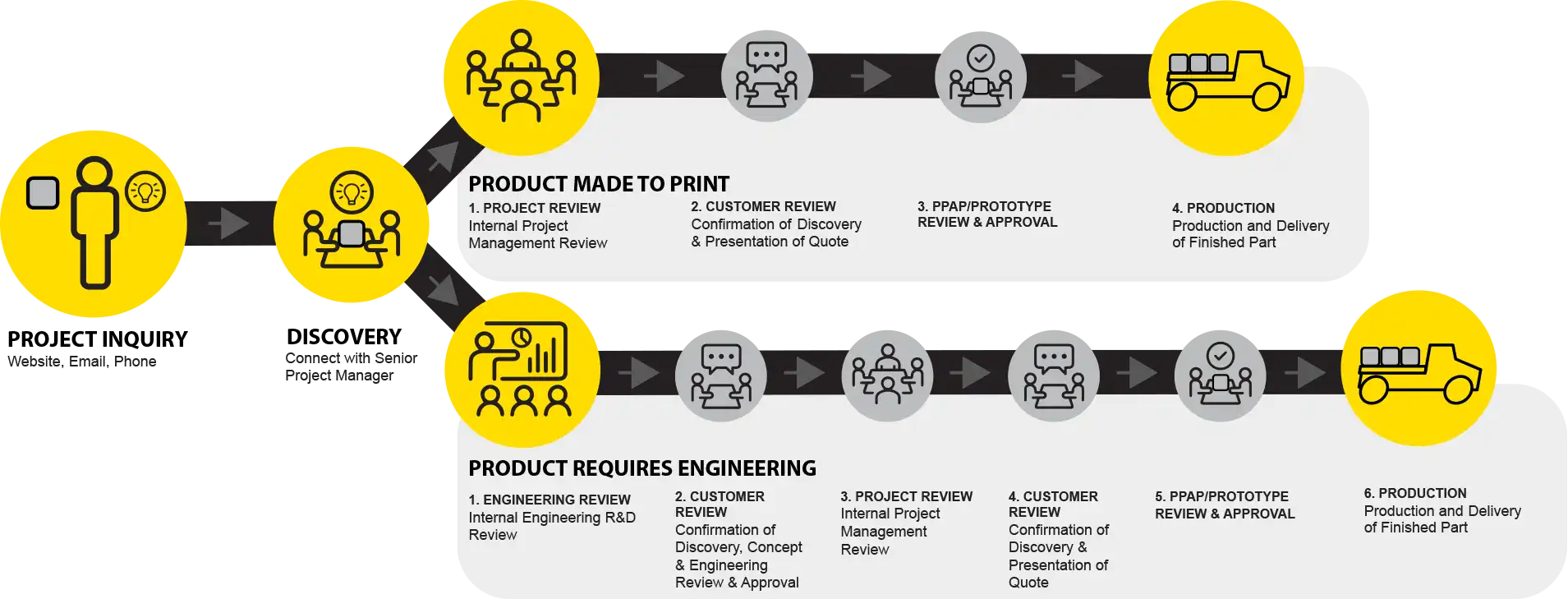

We solve these challenges by quickly connecting your team to our experienced staff to gain a clear understanding of your situation and what is needed to serve you best. In addition, Flextur maximizes machine tools and leverages available technology. We can greatly reduce the time from implementation to the delivery of finished product with our streamlined process.

Sheet Metal Fabrication Capabilities

Why Flextur?

Our Process